Blog

July 31, 2019

Banding | Thermal Head Power | Fly Off | Edge Detection

Misregistration | Electrostatic Issues | Out of Focus | No Exposure

These words may seem obscure to the general public, but print industry insiders know they can mean the difference between the success and failure of a print job.

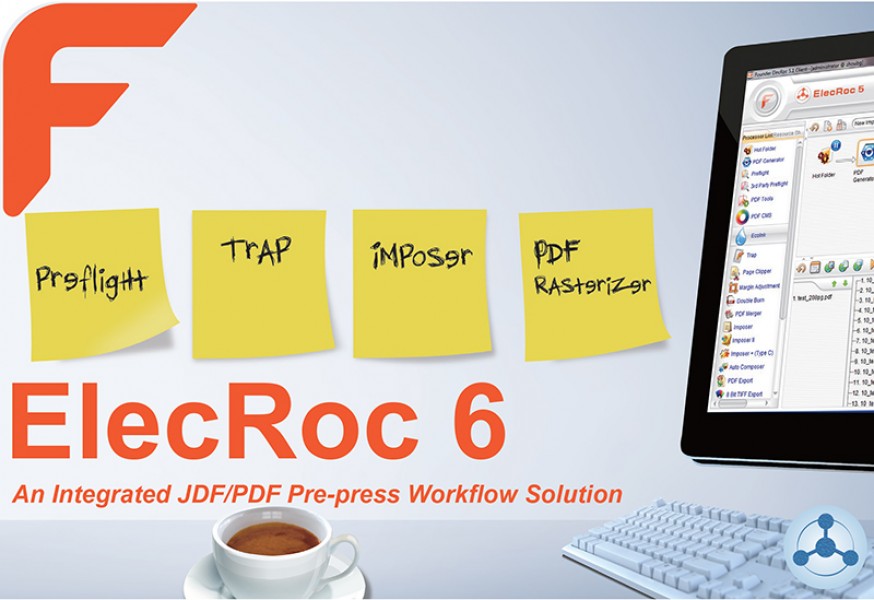

Prepress is often the key to print quality in terms of color, image, and general execution. So how do you guarantee success in this essential part of the print process?

We asked our network of experts about preventive approaches to ensure prepress quality at minimal cost, and here’s what they suggest:

1. Regular check-ups: many printers focus solely on number of hours in operation, and neglect to ensure that the performance of their prepress machine consistently meets manufacturer standards. Best practice in this area calls for regular checks, at least every 3 months

2. Banding: this common issue is often caused by the wrong power setting or a problem with focus. Checking these two areas first can help expedite the diagnosis process and determine whether expert help is required

3. Speed: too many printers keep their prepress machines at maximum speed and power, even when this is not necessary, which shortens the life of laser heads. Slowing down when possible may not save time, but definitely saves money

4. Plates: inexpensive plates may seem like a good deal, but it’s a good idea to consider overall cost rather than cost per plate. Some plates require high power to burn properly, which shortens laser life

For more tips please contact us